Logo Stamping Face-palm

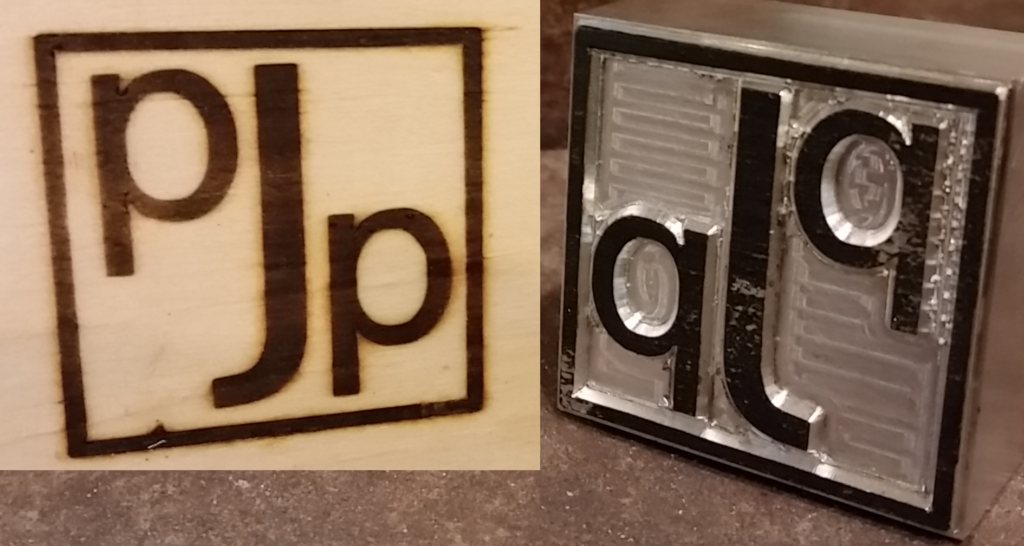

by Matt I think of myself as a relatively smart guy, but this dumb move had me wondering. When I first began making branding irons for people to stamp their logos on things, I sent out plain wood handles that looked nice and did the job, but opportunity was passing me by. Every single one […]

Logo Stamping Face-palm Read More »